The production of ceramics and sanitaryware requires managing various viscous and abrasive fluids. The type of pump used in the process significantly influences the operation’s efficiency and cost-effectiveness. Therefore, selecting the appropriate pump is crucial for optimising the production process.

Types of Pumps Used in the Ceramics and Sanitaryware Industry

In the ceramics and sanitaryware industries, various pump types are available, such as centrifugal pumps, gear pumps, and diaphragm pumps. Each type offers distinct pros and cons, making the choice dependent on the specific application’s requirements.

Why EODD Pumps are the Best Choice for the Ceramics and Sanitaryware Industry

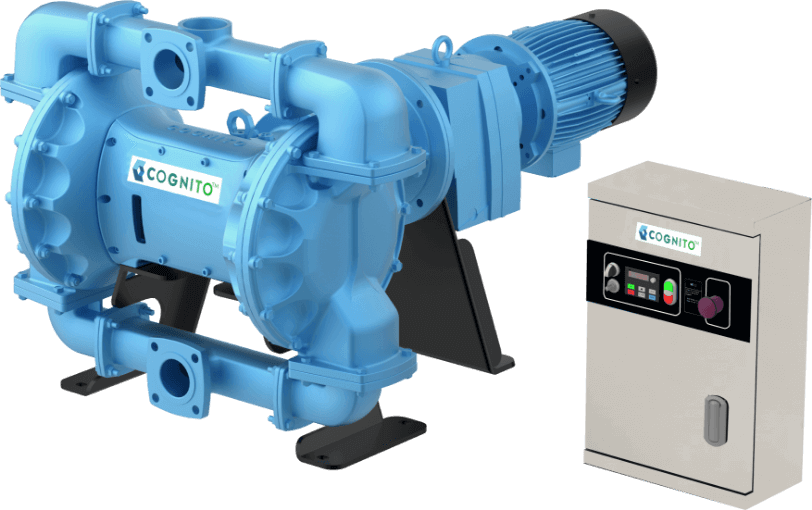

Electrically Operated Double Diaphragm (EODD) pumps are a modern technology designed for metering applications and fluid handling. Unlike standard double diaphragm pumps that operate pneumatically, EODD pumps are driven electrically. The CognitoTM EODD pump, specifically, stands out with its integrated surge suppression feature, making it an excellent and preferred choice for the ceramics and sanitaryware industries.

Detailed Explanation of CognitoTM EODD Pumps

EODD pumps are versatile and well-suited for handling various types of fluids, ranging from highly abrasive and corrosive to shear-sensitive and viscous fluids. Their standout feature is their exceptional energy efficiency, which leads to substantial reductions in energy consumption compared to other pump types. EODD pumps boast a robust mechanism, making maintenance hassle-free and contributing to low MTTR (Mean Time To Repair) and high MTBF (Mean Time Between Failures), ensuring reliable and long-lasting performance.

Mechanism of EODD Pumps

EODD pumps utilise a clever mechanism involving two interconnected diaphragms connected by eccentric shaft. When the shaft rotates & reaches a peak on the right side, at the same time reaches the valley on the left side of the chamber. This mechanism causes extrusion of the right diaphragm & intrusion of the left diaphragm. As a result positive pressure is built on the right side, pushing the fluid out of the chamber & vacuum on the left side, pumping the fluid inside the chamber. This reciprocating motion establishes a continuous and smooth flow of fluid through the pump, making it an efficient and reliable pumping solution

Features, Benefits, and Advantages of EODD Pumps

EODD pumps offer numerous valuable advantages, making them an excellent choice for various applications. They excel in handling highly abrasive, corrosive, shear-sensitive, and viscous fluids with ease. Their exceptional energy efficiency leads to significant reductions in energy consumption compared to other pump types. They boast a robust mechanism that requires minimal maintenance, leading to low MTTR and high MTBF. These pumps provide the added convenience of remote performance monitoring, ensuring seamless operation and performance optimisation.

Why IDEX CognitoTM is the Best Pump for the Ceramics and Sanitaryware Industry

The IDEX CognitoTM EODD Pump, integrated with IoT technology, is specifically designed to handle a wide range of viscous and abrasive fluids in various industries. It plays a vital role in supporting the Tableware, Insulator, Ceramics, and Sanitaryware sectors by facilitating high-speed production through secure bulk liquid transfer. Market-leading sanitaryware producers have benefited from the implementation of the IDEX CognitoTM EODD pump, experiencing improved outcomes and reduced production waste.

Conclusion

The IDEX CognitoTM EODD Pump proves to be an outstanding option for the ceramics and sanitaryware industries, thanks to its remarkable capability in managing diverse viscous and abrasive fluids with utmost efficiency. With its resilient construction, exceptional performance, and advanced IoT-enabled features, this pump not only enhances production efficiency but also lowers the overall cost of ownership. It is a reliable and cost-effective solution for meeting the industry’s demanding needs and ensuring smooth operations.