The ever-evolving industrial landscape of India demands efficiency and versatility to deliver uncompromised growth. A vast range of pumps, motors, and machines has powered industries over the years. Especially when it comes to fluid handling, diaphragm pumps have been the backbone for industries. Now, with the advent of new and better technology, the regular diaphragm pumps are losing their edge.

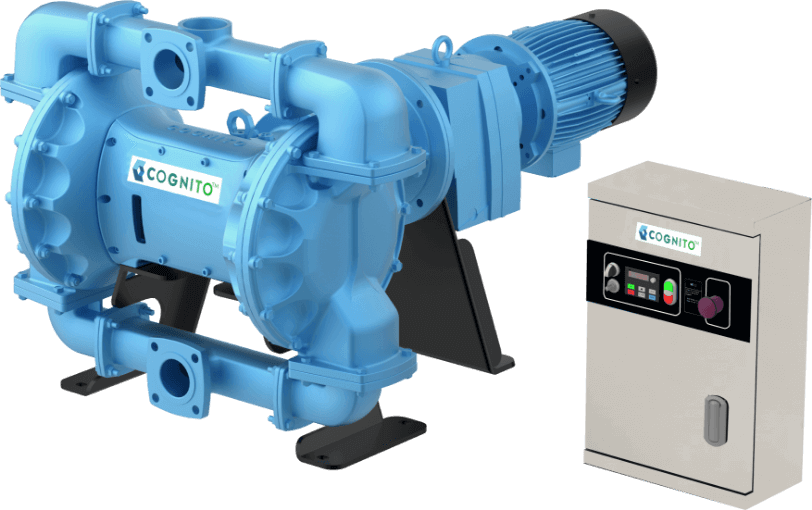

Electrically operated double diaphragm pumps like the Cognito EODD are changing the scene for good. Let’s dive deeper into why Cognito EODD pumps are fast being recognised as the best-in-class diaphragm pumps in India.

Diaphragm Pumps: The Heroes of Fluid Transfer

Air-operated and manually-driven traditional diaphragm pumps have been the preferred liquid transfer solution for the longest time. They have been known to handle a wide range of fluids, right from delicate chemicals to viscous slurries. They have qualities like:

- Self-priming

- Shear tolerance

- Clog-resistance

That makes them the preferred choice in industries like chemical processing, pulp & paper, ceramics & sanitaryware, food & beverages, and water & wastewater.

Industry-Specific Roles of Diaphragm Pumps

In the chemical processing industry, traditional diaphragm pumps are used for handling corrosive chemicals, slurries, and viscous fluids. In the pulp & paper industry, they are used to transfer pulp suspensions and abrasive fluids. In the ceramics & sanitaryware industry, they are used for handling slips, slurries, and glazes. The food & beverage industry uses these pumps to handle syrups, pastes, and other viscous fluids. And, in the water & wastewater treatment industry, these pumps are used for transferring wastewater, sludge, and chemicals.

Shortcomings and Limitations of Diaphram Pumps

Despite being a driving factor in all these industries, traditional diaphragm pumps are not perfect. They have their own specific set of limitations, too. The air-operated diaphragm pumps need compressed air to operate. This phenomenon adds a layer of complexity, thus raising the maintenance cost. On the other hand, manual pumps are labour-intensive. They are also inefficient for large-scale operations.

That’s precisely where the EODD pump takes the cake. They offer the versatility of the traditional diaphragm pump without its troubles. It eliminates the challenges of traditional pumps by using electric power to offer unmatched precision and convenience.

Electric Diaphragm Pumps: Powering the Shift

Electric double diaphragm pumps, like the Cognito EODD, offer a plethora of advantages over their traditional counterparts:

- Energy Efficiency: Cognito EODD pumps consume significantly less energy compared to air-operated pumps, leading to substantial cost savings and reduced environmental impact.

- Precise Control: Variable speed control allows for fine-tuning flow rates and pressures, optimising processes, and minimising waste.

- Reduced Maintenance: Cognito EODD pumps have fewer moving parts compared to air-operated pumps, resulting in lower maintenance requirements and downtime.

- Clean and Quiet Operation: No compressed air means quieter operation and a cleaner work environment.

- Improved Safety: Eliminates the risk of compressed air leaks and associated safety hazards.

Cognito EODD: Where Innovation Meets Excellence

IDEX, a global leader in fluid and material handling technologies, presents the Cognito EODD. Here’s what sets Cognito apart:

- Superior Performance: Boasting high flow rates, excellent suction lift capabilities, and handling fluids with viscosities up to 15,000 cps, Cognito tackles the toughest jobs with ease.

- Unmatched Durability: Robust design and premium materials ensure long-lasting operation and minimal wear-and-tear, even in harsh environments.

- Smart Intelligence: Cognito EODD is IoT-enabled, allowing for remote monitoring, predictive maintenance, and data-driven insights for optimising performance and efficiency.

- Sustainable Choice: Built with energy-efficient operation and minimal environmental impact in mind, Cognito is a responsible choice for environmentally conscious businesses.

Beyond Cognito, IDEX offers a diverse range of EODD pumps under the Warren Rupp® and Burkert® brands, catering to a wide spectrum of industry needs and applications.

Data-Driven Optimisation: The Future Is Now

Forget clunky logbooks and reactive maintenance. Cognito EODD embraces the future with its IoT-enabled features. The Cognito EODD enables you to monitor the pump’s health at all times through real-time performance data. The same feature also lets you optimise maintenance schedules by predicting any potential issues in advance. The data-driven insights will help you not only minimise the downtime but also extend the pump life. Now, that’s futuristic!

Beyond Cognito: IDEX as Your Diaphragm Pump Partner

While Cognito shines brightly, it’s only one star in the vast IDEX galaxy. Warren Rupp® and Burkert® brands offer a diverse range of EODD pumps, specifically engineered for various industries and applications. From compact, battery-powered options for portable tasks to heavy-duty industrial giants, IDEX provides the perfect pump for your unique needs.

Investing in the Future: Choose Cognito, Choose IDEX

With the Cognito EODD pump comes the prowess of innovation and efficiency. With data-driven insights and an unwavering commitment to sustainability, the Cognito EODD comes prepared to deliver an absolutely delightful performance. Add IDEX’s overall expertise in the domain and its expansive portfolio, and you’ll find your business being propelled forward with the assurance of an all-rounder diaphragm pump.

Choosing the Right EODD Pump for Your Needs

With the rising demand for efficiency and sustainability, we are rapidly gaining traction in the Indian market. When choosing the right pump for your application, consider factors like:

- Fluid type and viscosity

- Flow rate and pressure requirements

- Material compatibility

- Control options and features

- Budget and maintenance considerations

Why is it Essential to Consider these Factors?

Since different pumps are suited for different fluids and viscosities, it is necessary to consider the fluid type and viscosity before choosing an ideal pump for your usage. Similarly, it is essential to match the pump’s capabilities to your specific flow rate and pressure requirements. Considering the compatibility of the pump’s materials with the fluids you plan to process and handle is also an essential part. It is essential to carefully consider and choose a pump that offers the desired level of control and automation. Lastly, factors like the initial cost, maintenance requirements, and energy efficiency should also be on your radar.

Conclusion

By carefully evaluating your needs and exploring the comprehensive offerings from IDEX, including the cutting-edge Cognito EODD, you can unlock the power and efficiency of electric diaphragm pumps and propel your operations to the next level.

Embrace the future of fluid handling with IDEX and experience the unparalleled performance and innovation of Cognito EODD, the best-in-class electric diaphragm pump redefining the industry in India.